An important rural industry

Sugarcane is an important rural industry for Australia, worth $2.5 billion to the economy annually. Approximately 3,700 cane farm businesses grow 30 million tonnes of cane each year. This cane is crushed and processed at 22 Australian sugar mills to produce 4 million tonnes of raw sugar and other by-products.

Sugarcane is a ratooning crop that will regrow for up to five or six years before needing to be replanted. Often farmers grow other crops like soybeans, bananas or horticultural crops for crop to break up the monoculture and assist with soil health.

The complete sugarcane paddock to packet cycle contains multiple steps, from the planting of sugarcane through to the exporting of raw sugar crystals to international markets, or the refining and packaging of sugar for domestic use.

Although 'raw' sugar is the main product of Australian sugarcane, a host of other products are made from the sugarcane plant including ethanol, molasses, mulch, plastics, clothing, and pharmaceuticals.

Sugarcane growers plant sugarcane crops using land management practices that ensure the sustainable growth of the plants and the health of their soils.

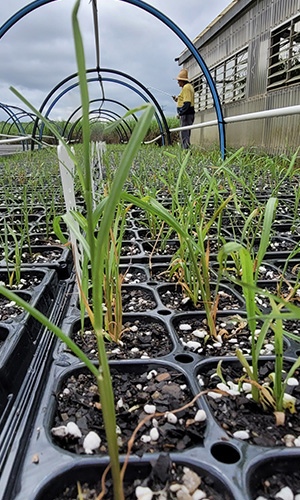

Sugarcane is grown by replanting a section of the stalk of a mature cane plant, called a billet.

New shoots grow from buds on the planted billet, to grow successfully, sugarcane needs strong sunlight, fertile soil, and sufficient water. Throughout the growing process crops must be monitored for pests and diseases.

Sugarcane growers embrace innovations in technology and machinery to ensure maximise efficiency and profitability. This may include remote sensing for crop inputs, drones, and GPS guided machinery.

In Australia, sugarcane is harvested from June-December, as these months typically see less rainfall in cane growing regions.

Large mechanical harvesters cut the cane stalks off at its base. As they move down each row, the cane is collected and cut into shorter 30cm length pieces known as billets. The leaf matter is blown out the back of the harvester to be used across the fields as a natural mulch or trash blanket.

To minimise sugarcane deterioration and juice evaporation, sugarcane should be transported to a sugar mill within 16 hours of being harvested.

The cane is loaded into trucks (for road transport) or mill bins at local sidings on the nearest dedicated cane railway track (for rail transport). Most of the cane travels to the mill on this extensive mill owned rail network.

At the sugar mill, the juice is extracted from the stalk through a crushing process. The sugar crystals are then extracted from the juice. Although 'raw' sugar is the main product of Australian sugarcane, there are a host of other uses for the plant. Molasses is a dark syrup separated from raw sugar crystals during the milling process. It is used as a raw material for ethanol as renewable fuel and rum and as an animal feed supplement.

The left-over fibre from the stalk is called bagasse. Bagasse is used by the mills to generate electricity to power the sugar mill, excess power is provided back to the energy grid. Other by-products include a residue used as a fertiliser on cane farms, and excess fibre can be made into plastics, fibre board and biopharmaceuticals.

Some raw sugar goes to Australian refineries where the raw sugar crystals are washed and dissolved in hot water. Any remaining colours and impurities are removed, and the pure sugar is boiled and seeded with fine sugar crystals.

When the crystals are large enough, they are tumble dried to remove moisture. The dried sugar is then graded into sizes and packaged for delivery to customers.

85% of an raw sugar crystal produced in Australia is exported to other countries, including South Korea, Japan, Indonesia, Malaysia, USA and UK.

When the raw sugar arrives in these countries it is refined ready for use as an ingredient for some of the world's largest food companies.

Sugar Research Australia

Sugar Research Australia

SRA invests in and manages the research and development efforts of the sugar industry. It is funded by a statutory levy paid by grower and miller businesses and funds and grants from government and other bodies.

The SRA website has information and advice on varieties of sugarcane, farming systems (including soil health and nutrient management), pests and diseases and weeds.

Australian Sugar Milling Council

Australian Sugar Milling Council

ASMC is the peak body for raw sugar mill owners in Australia. Its website lists its members and has recent industry production statistics.

Milling process

Milling process

How is the raw sugarcane processed into sugar you can eat? Wilmar Sugar Australia has an informative video exploring the milling process.